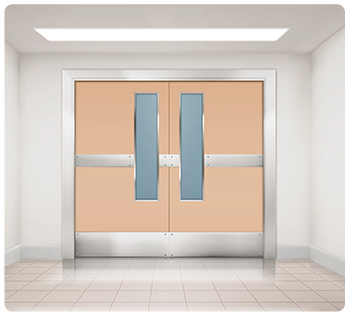

In case of fire, one of the primary concerns is to prevent it from spreading till help arrives.

Contain Fire & Smoke for up to 2 hours

Timex Fire Retardant Doors have high-safety standards. They are designed to provide maximum protection

to life and property in case of fire. While the main body of the door holds back the fire, the

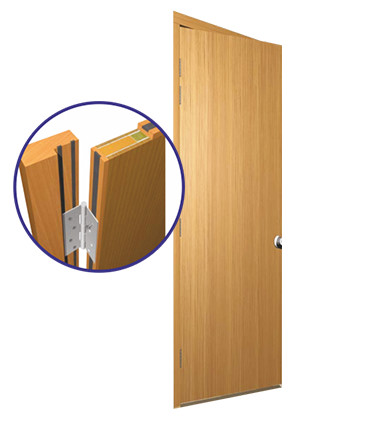

intumescent strip on the edges swells to fill the gap between the door and the frame,

preventing smoke as well as flames from passing through.

Choice of Rating & Thickness

Rating

THICKNESS : 45 mm

Rating

THICKNESS: 45 mm, 50 mm

Rating

THICKNESS: 45 mm, 50 mm, 55 mm

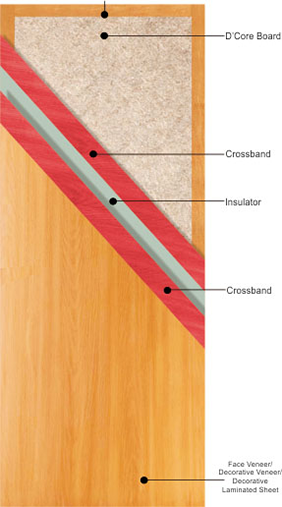

Construction

Thermal insulation at the core

Both sides layered with insulator

Finishing done with waterproof, PF-bonded plywood on both sides

Fire and smoke sealing graphite strip on sides

Salient Features

High in strength

impact resistant

resistant to insect, borer & Fungi

Tested in Indian Plywood Industries

Research & Training Institute (IPIRTI)

Conforming to BS-476 & IS-3614

FIRE-RATERDANT DOOR FRAMES:

To suit to our Fire-Retardant Door Shutters for Door Frames made out of

Fire-Retardant-Cum-Antiseptic Treated and Seasoned Timber.

Timex Fire Retardant Doors

Conform to BS-476 & IS-3614

IPIRTI (Bangalore) Certified

as per BS 476 part 20 & 22

Applications

High-rise buildings (Commercial & Residential):

ELEVATORS

staircases

Doors for entrances

terraces

Hotels:

reception areas

kitchens

floor lobbies

service areas

Hospitals:

Doors for lobby

operation theatres

labs

electric ducts

30 Minutes F. R. Doors

60 Minutes F. R. Doors

Finger joint Stile/Rail

Seasoned and Treated

Timber of 45-60

120 Minutes F. R. Doors

30-Minute Fire Retardant Doors:

The glued crossband / HDF / veneer and face veneer of combined

thickness of 5/6 mm is applied on both sides of the fire-core board type frame.

The same is hot pressed under temperature of 140-150 C and pressure of 14-16 kg/cm2.

60/120 minute fire retardant doors:

Adequate thickness of resin impregnated heat insulator is layered on both surfaces.

The glued crossband / HDF / veneer and face veneer of combined thickness

of 5/6 mm are applied on both sides of the fire core board type frame.

The same is hot pressed under temperature of 140/1500> C and pressure of 14-16 kg/cm2.